Digital Manufacturing Revolution: Industry Set to Skyrocket by $1.6 Trillion in Groundbreaking Transformation

Digital Manufacturing Market: Navigating Growth and Transformation in the Global Industrial Landscape

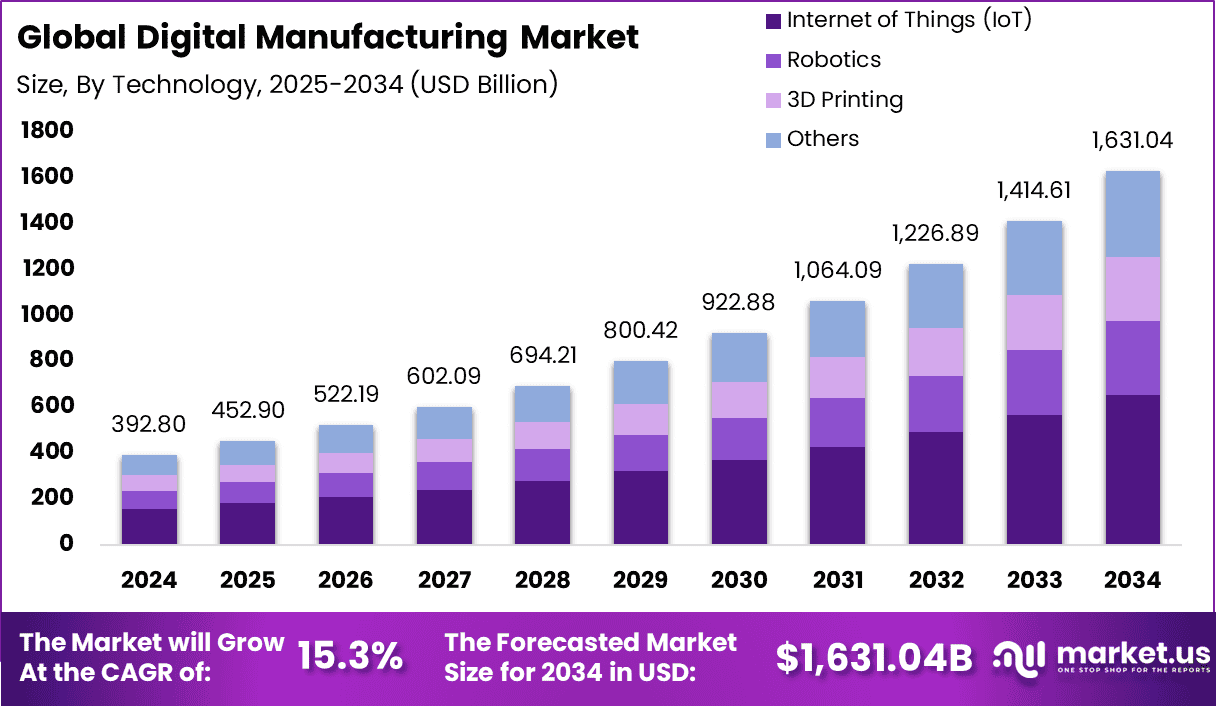

The digital manufacturing market is poised for remarkable expansion, with projections indicating significant growth and transformative developments through 2025-2034. As global industries increasingly embrace technological innovation, the sector is experiencing a profound revolution driven by advanced manufacturing technologies and strategic adaptations to changing economic landscapes.

Key Market Dynamics

The ongoing US tariff impacts are reshaping the digital manufacturing ecosystem, compelling companies to reimagine their production strategies and technological investments. Manufacturers are leveraging cutting-edge digital technologies to enhance operational efficiency, reduce costs, and maintain competitive advantages in an increasingly complex global market.

Technological Innovations Driving Growth

- Advanced robotics and automation

- Internet of Things (IoT) integration

- Artificial Intelligence and machine learning applications

- Cloud-based manufacturing platforms

The forecast period from 2025 to 2034 promises unprecedented opportunities for digital manufacturing, with emerging technologies and strategic adaptations positioning industry leaders to capitalize on global market transformations.

Strategic Outlook

Companies are increasingly investing in digital transformation, recognizing that technological innovation is no longer optional but essential for survival and growth in the rapidly evolving manufacturing landscape.