From Robots to Revolution: Inside the High-Tech Future of Manufacturing

Smart Factories: The Future of Manufacturing Powered by Artificial Intelligence

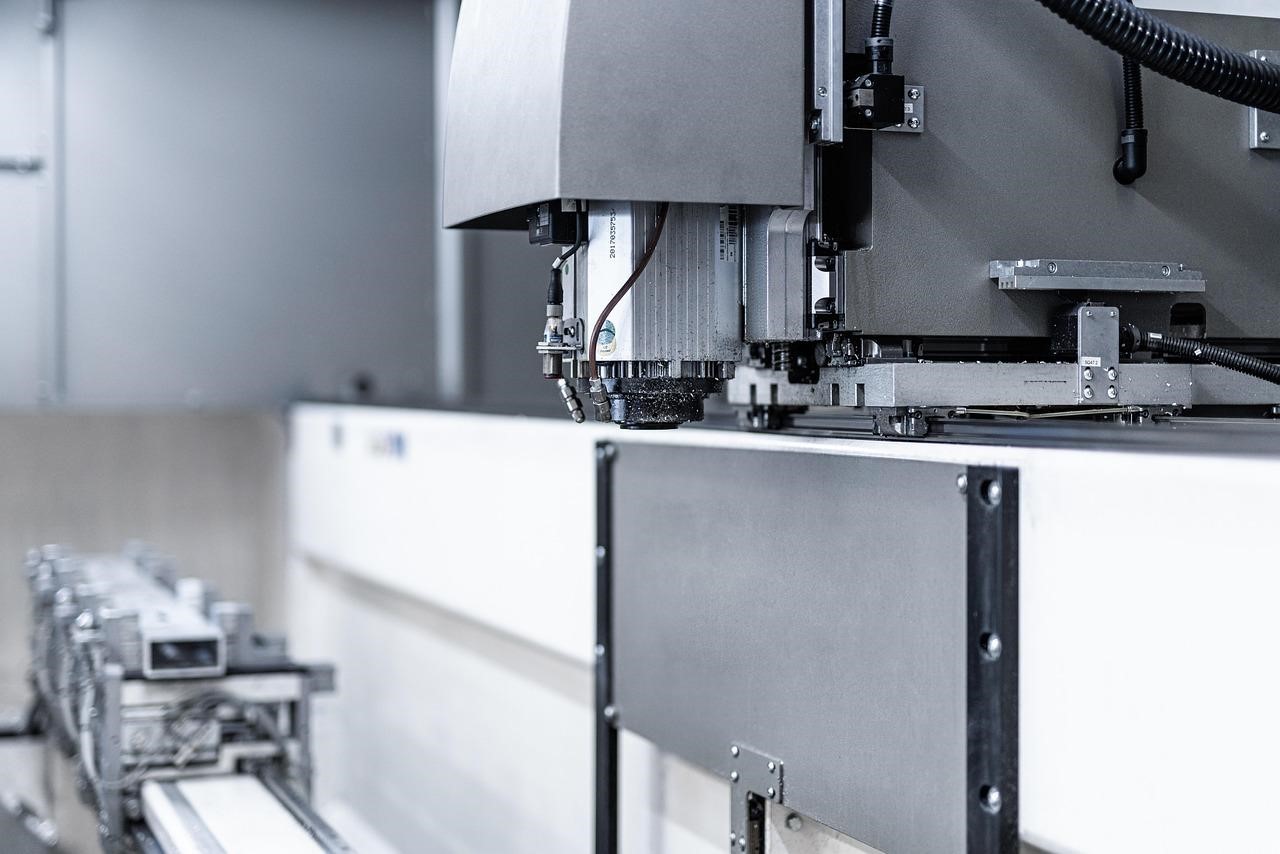

In the rapidly evolving landscape of industrial innovation, smart factories are revolutionizing manufacturing by seamlessly integrating cutting-edge artificial intelligence and machine learning technologies. These advanced facilities transform traditional production environments by embedding intelligent software that can dynamically interpret and analyze complex data streams from machines, sensors, and intricate workflow processes.

By leveraging sophisticated AI algorithms, smart factories can now predict equipment maintenance needs, optimize production efficiency, and make real-time decisions that were once impossible. The intelligent systems continuously learn from operational data, identifying patterns and potential improvements that human operators might overlook.

These AI-driven factories are not just about automation, but about creating a responsive, adaptive manufacturing ecosystem. Sensors strategically placed throughout production lines collect massive amounts of data, which intelligent software then processes and translates into actionable insights. This means reduced downtime, enhanced product quality, and unprecedented levels of operational precision.

As technology continues to advance, smart factories represent the next frontier of industrial transformation, where artificial intelligence and human expertise collaborate to push the boundaries of manufacturing excellence.