Zap-Proof Tech: How Semiconductor Giants Are Battling Invisible Electronic Threats

Breakthrough in Electrostatic Discharge Monitoring for Semiconductor Manufacturing

Researchers from National Yang Ming Chiao Tung University have unveiled a groundbreaking technical paper that promises to revolutionize electrostatic discharge (ESD) protection in semiconductor manufacturing. The innovative study, titled Real-Time ESD Monitoring and Control in Semiconductor Chip Environments, addresses a critical challenge in the electronics industry.

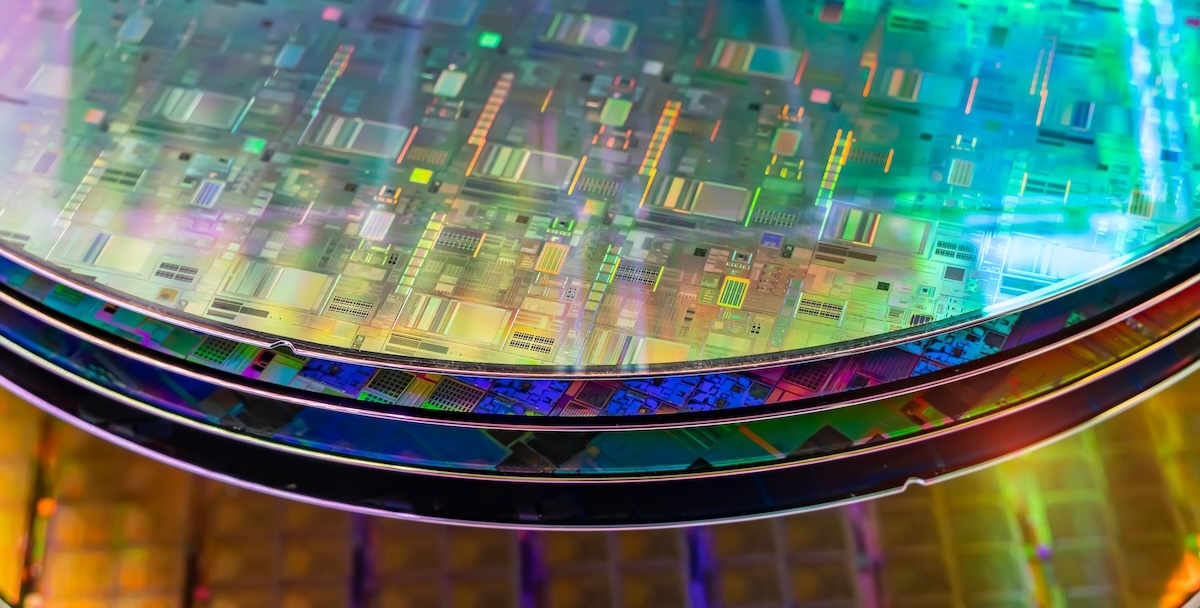

Integrated circuits are incredibly delicate and vulnerable to electrostatic discharge events, which can cause catastrophic damage to sensitive electronic components. The research team has developed a cutting-edge silicon chip capable of real-time detection and immediate alerting of potential ESD events, potentially saving millions of dollars in manufacturing losses.

By providing instantaneous monitoring and control mechanisms, this breakthrough technology offers semiconductor manufacturers an unprecedented level of protection against the invisible threat of electrostatic discharge. The novel approach could significantly improve production reliability and reduce costly equipment failures.

As electronic devices become increasingly complex and miniaturized, the importance of advanced ESD protection cannot be overstated. This research represents a significant step forward in safeguarding the intricate world of semiconductor manufacturing.