Smart Factories: The Game-Changing Tech Transforming Industry, But Funding Gaps Remain

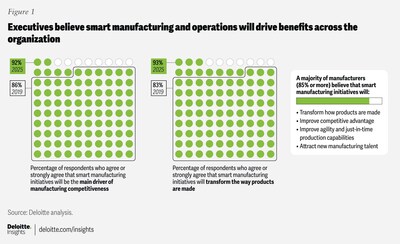

In a groundbreaking survey by Deloitte, the transformative power of smart manufacturing has emerged as a critical competitive advantage for businesses, while simultaneously highlighting the need for strategic investment and thoughtful implementation.

The research reveals that forward-thinking manufacturers are increasingly embracing advanced technologies to revolutionize their production processes. Smart manufacturing isn't just a trend—it's becoming a fundamental strategy for companies seeking to stay ahead in a rapidly evolving industrial landscape.

Key findings from the survey underscore the significant potential of smart manufacturing technologies. Companies that successfully integrate intelligent systems are experiencing remarkable improvements in operational efficiency, product quality, and overall productivity. These technologies, including artificial intelligence, Internet of Things (IoT) sensors, and advanced analytics, are reshaping traditional manufacturing paradigms.

However, the survey also illuminates a crucial challenge: while many organizations recognize the potential of smart manufacturing, many struggle with effective implementation. Successful digital transformation requires more than just technological investment—it demands a comprehensive approach that includes workforce training, cultural adaptation, and strategic planning.

Experts recommend that businesses take a holistic approach to smart manufacturing adoption. This involves not only investing in cutting-edge technologies but also developing a robust ecosystem of skills, processes, and organizational capabilities that can fully leverage these innovative tools.

As manufacturing continues to evolve, those companies that can effectively integrate smart technologies will likely gain a significant competitive edge. The Deloitte survey serves as a compelling call to action for manufacturers to embrace digital transformation with vision, commitment, and strategic insight.