Revolutionary Nano-Tracking: How One Technique Could Transform Manufacturing Forever

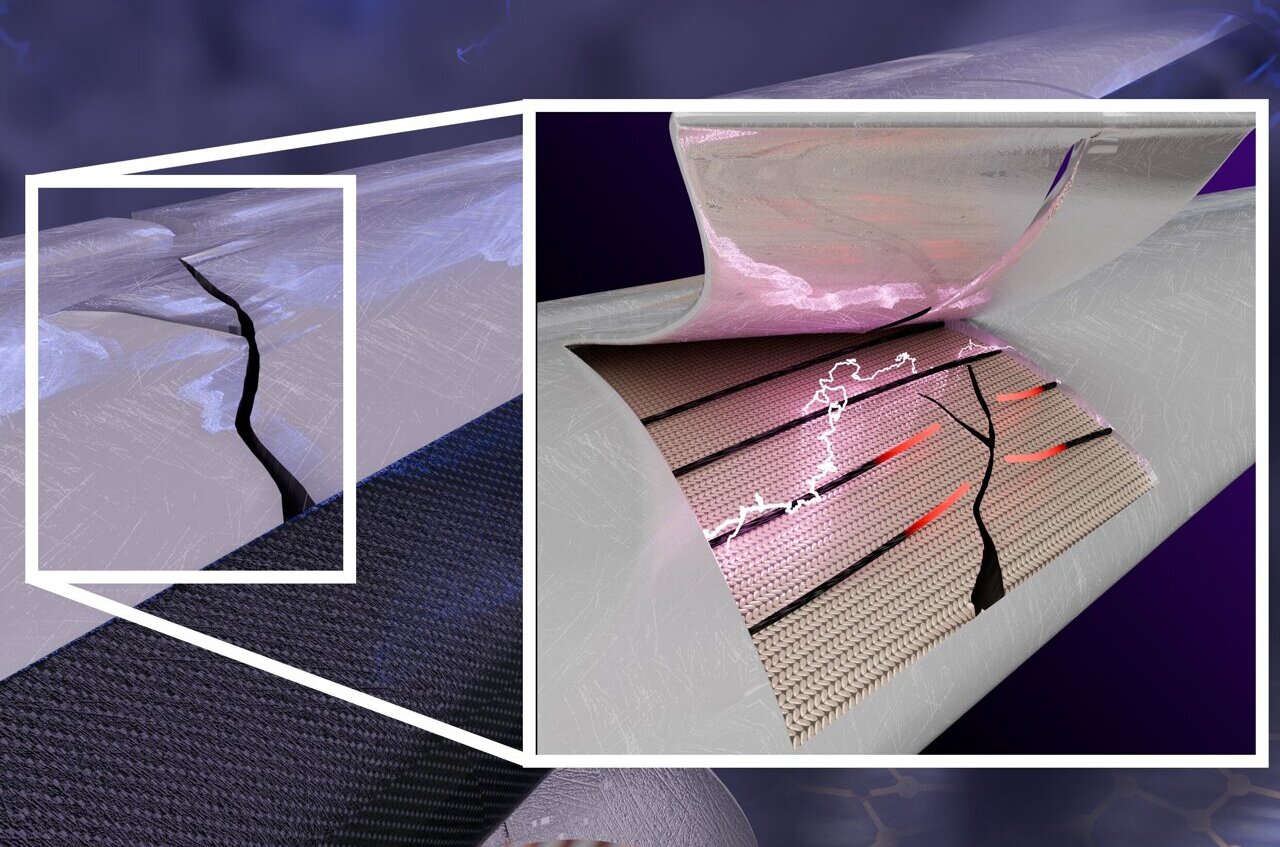

Researchers at Skoltech have pioneered a groundbreaking approach to material monitoring that promises to revolutionize how we understand and analyze multifunctional materials. The collaborative effort between the Laboratory of Nanomaterials, Hierarchically Structured Materials Laboratory, and Materials Center has developed an innovative dual-stage monitoring technique that offers unprecedented insights into complex material structures.

This cutting-edge method represents a significant leap forward in materials science, providing researchers with a more comprehensive and nuanced understanding of material behavior. By implementing a two-stage monitoring process, scientists can now detect and analyze intricate changes at both microscopic and macroscopic levels with remarkable precision.

The novel technique demonstrates the power of interdisciplinary collaboration, showcasing how advanced research can push the boundaries of scientific understanding. Researchers are particularly excited about the potential applications across various fields, including advanced manufacturing, aerospace, and nanotechnology.

While the full details of the technique remain under careful study, early indications suggest this approach could dramatically improve material performance assessment, quality control, and predictive maintenance strategies across multiple industries.