Electric Vehicle Supply Chain Booms: Component Makers Ride the Green Revolution Wave

LAYANA Accelerates Electric Vehicle Component Manufacturing with Cutting-Edge Technologies

LAYANA, a leading manufacturing innovator, has announced remarkable growth in electric vehicle (EV) component production, marking a significant milestone in the automotive supply chain. The company's success stems from strategic technological advancements and a bold global expansion strategy.

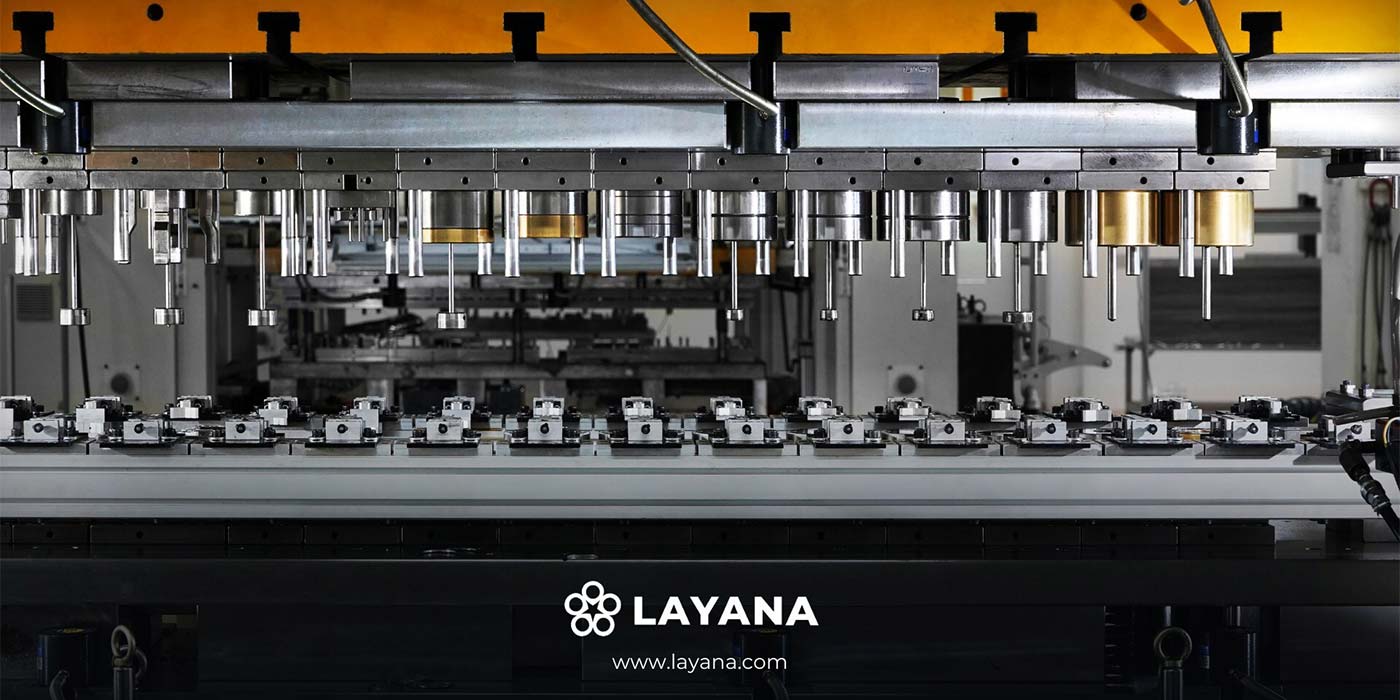

At the heart of LAYANA's breakthrough are sophisticated manufacturing techniques like overmolding and insert molding, which have revolutionized the precision and quality of EV components. These advanced processes enable the creation of complex, high-performance parts that meet the increasingly demanding specifications of modern electric vehicles.

The company's commitment to innovation has positioned it as a key player in the rapidly evolving EV market. By investing in state-of-the-art manufacturing technologies and expanding its global footprint, LAYANA is not just responding to the electric vehicle revolution—it's actively shaping the future of automotive manufacturing.

Industry experts predict that LAYANA's record growth signals a promising trajectory for the company and reflects the broader momentum in electric vehicle component production worldwide.