Digital Manufacturing Gets a Boost: ModuleWorks Unveils Cutting-Edge 2025.04 Update

ModuleWorks Unveils Innovative Curve Preservation Feature in Latest 2025.04 Release

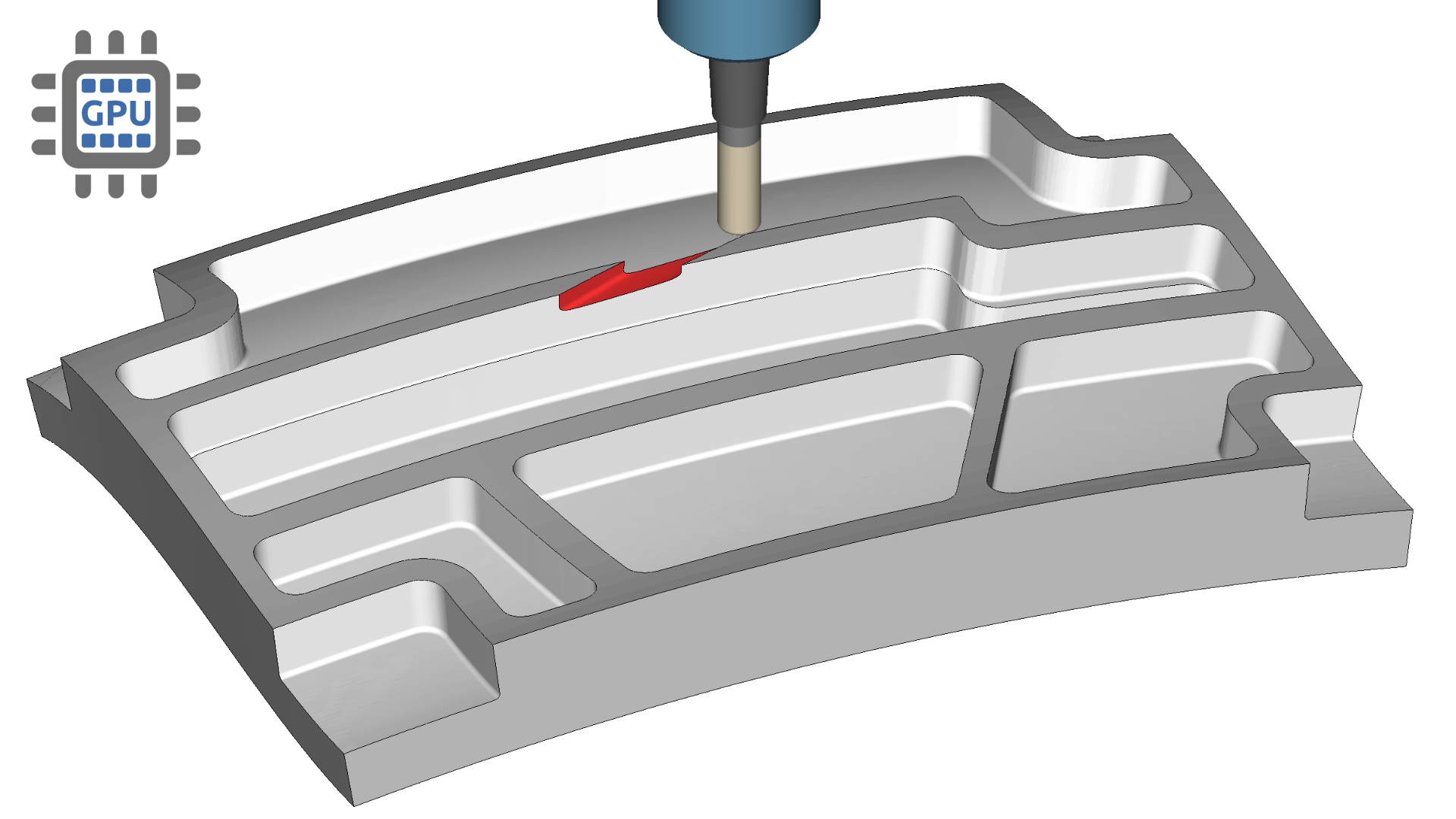

CAD/CAM software developer ModuleWorks has introduced an exciting new capability in its 2025.04 version that gives manufacturing professionals unprecedented control over toolpath generation. The latest update allows users to maintain the original input order of curves when creating sorted toolpaths, addressing a long-standing challenge in precision machining.

This groundbreaking feature empowers engineers and CNC programmers to preserve the exact sequence of curve inputs, ensuring more predictable and precise toolpath strategies. By maintaining the original curve order, manufacturers can now achieve greater consistency and control in their machining processes, particularly in complex geometric designs.

The curve input order preservation represents a significant advancement in toolpath generation technology, providing users with enhanced flexibility and accuracy in their manufacturing workflows. ModuleWorks continues to demonstrate its commitment to innovation by delivering solutions that directly address the nuanced needs of modern manufacturing professionals.

Designers and engineers can now look forward to more intuitive and reliable toolpath generation, with the assurance that their original curve input intentions are precisely respected throughout the machining process.