Breaking: St. Petersburg Unveils Massive 3D Printing Powerhouse, Shattering Global Manufacturing Boundaries

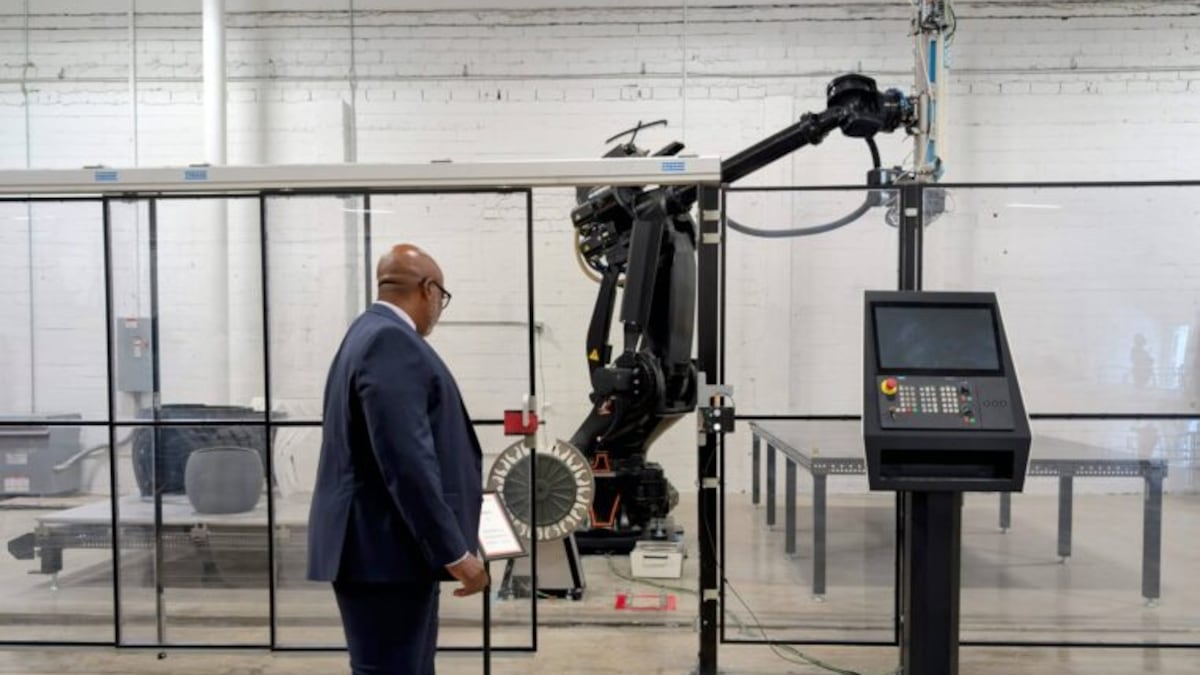

Haddy is revolutionizing sustainable manufacturing by harnessing the power of cutting-edge technology. The innovative company has developed a groundbreaking approach to production, utilizing eight advanced robots equipped with sophisticated artificial intelligence and machine learning capabilities. These intelligent machines specialize in 3D printing furniture and various products using recycled materials, transforming waste into beautiful, functional designs.

By combining state-of-the-art robotics with environmental consciousness, Haddy is not just creating products, but pioneering a new era of eco-friendly manufacturing. Their robotic system can analyze, process, and transform recycled materials into high-quality items with remarkable precision and creativity. This approach not only reduces waste but also demonstrates how technology can be a powerful tool in sustainable design and production.

The company's unique method represents a significant leap forward in green manufacturing, showing how artificial intelligence can be leveraged to create innovative solutions that benefit both consumers and the environment. Haddy's robots are more than just machines; they are the architects of a more sustainable future.