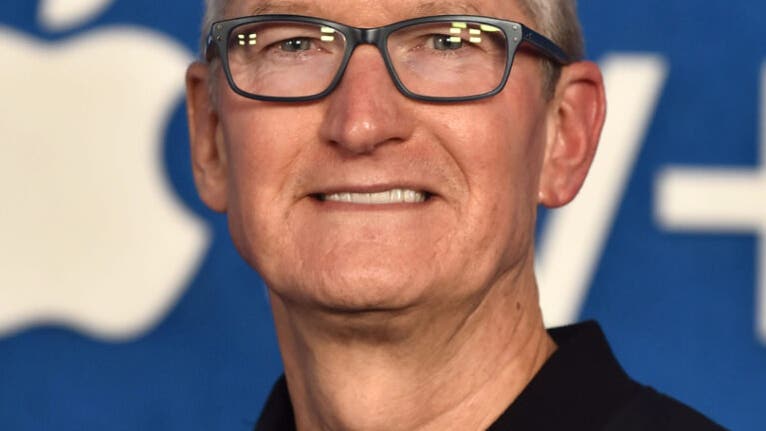

Inside Apple's US Manufacturing Pivot: Tim Cook's Bold Vision Unveiled

Apple's Tim Cook Explores Potential US iPhone Manufacturing Shift

Apple Inc. (NASDAQ:AAPL) CEO Tim Cook is considering a significant strategic move that could potentially relocate iPhone production to the United States, according to recent discussions with U.S. Commerce Secretary Howard Lutnick.

During an interview on CNBC's "The Exchange" on Tuesday, Lutnick revealed insights from his conversation with Cook about the possibility of bringing iPhone manufacturing back to American soil. This development comes amid growing geopolitical tensions, trade uncertainties, and ongoing efforts to diversify global supply chains.

The potential relocation of iPhone production is particularly noteworthy given the current complex global manufacturing landscape. Traditionally, Apple has relied heavily on manufacturing partners in Asia, primarily in China, but recent economic and political dynamics are prompting a reevaluation of this strategy.

While specific details of the potential manufacturing shift remain unclear, the discussion signals Apple's openness to exploring domestic production options. Such a move could have significant implications for the U.S. manufacturing sector and Apple's global supply chain strategy.

As trade tensions continue and companies seek more resilient production models, Cook's exploration of U.S. manufacturing represents a potentially transformative approach to Apple's long-term operational planning.