Breaking: JLL Clinches $Multi-Million Financing for Cutting-Edge Manufacturing Hub Near Boston

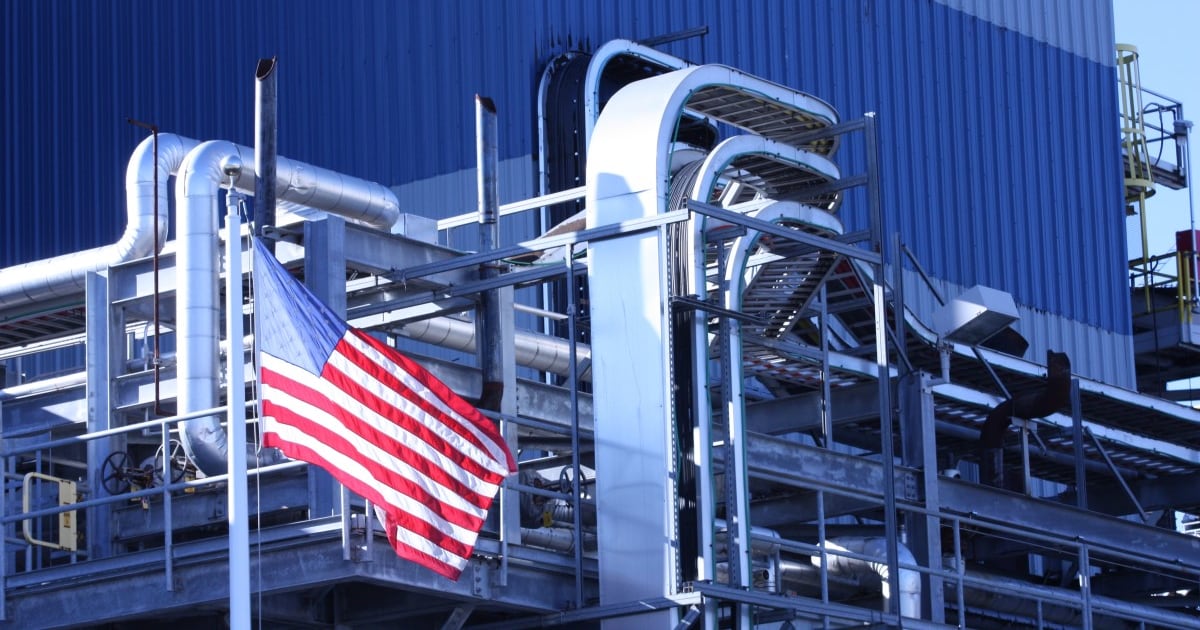

Boston-based JLL Capital Markets has successfully secured financing for a cutting-edge advanced manufacturing and research facility located in the heart of Hopkinton, Massachusetts. The property at 68-78 Elm Street represents a significant investment in the region's innovative industrial landscape, spanning an impressive 198,336 square feet. The financing deal, brokered by JLL's expert Capital Markets team, highlights the growing demand for sophisticated manufacturing and research spaces in the Greater Boston area. Working closely with the property's borrower, JLL demonstrated its prowess in navigating complex real estate financial transactions. This strategic financing arrangement underscores the continued strength of Massachusetts' advanced manufacturing and research sector, positioning the Hopkinton facility as a prime example of the state's commitment to technological innovation and industrial development.